Pointfar Automation

Reverse Engineer – Digital-to-Physical Workflow Reconstruction

Reverse Engineer – Digital-to-Physical Workflow Reconstruction

Couldn't load pickup availability

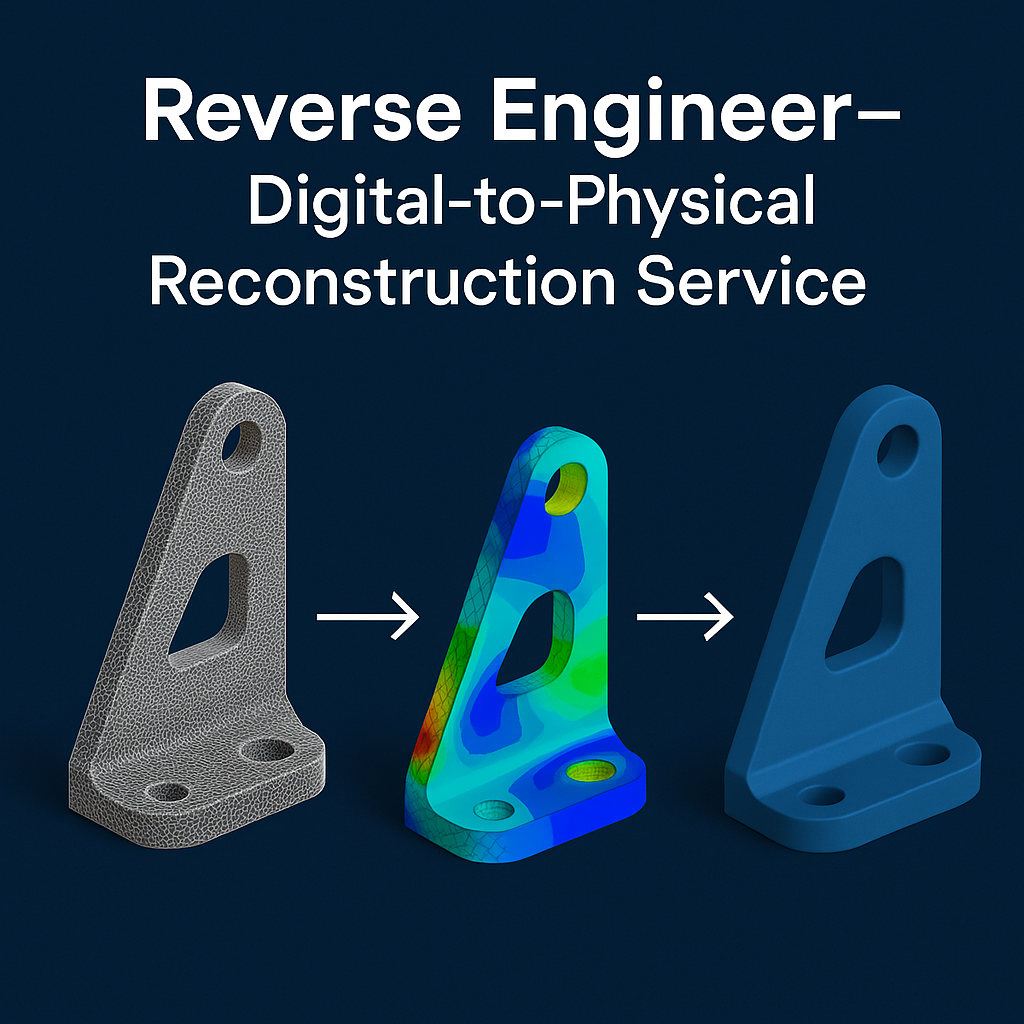

Reverse Engineer – Digital-to-Physical Workflow Reconstruction Service

Short Description

A specialized service for reconstructing, repairing, and optimizing scanned geometry, enabling smooth transitions between the physical and digital worlds. Perfect for mesh cleanup, scan remodeling, 3D printing preparation, and digital-twin accuracy validation.

Full Description

Reverse Engineer is a dedicated, best-in-class reconstruction solution for any workflow involving a transition between the physical and digital worlds. Whether you are working with scans, meshes, simulation results, prototype data, or production validations, this service delivers precise geometry rebuilding, optimization, and export-ready outputs.

We import, refine, repair, and remodel digitized data—including raw meshes, 3D scans, or large point clouds—into high-quality, CAD-accurate geometry. Reverse Engineer also enables deformation compensation (spring-back, thermal effects, etc.), digital twin comparison, and 3D-printing file generation.

This service is ideal for engineering teams, manufacturers, industrial designers, prototype labs, and R&D groups requiring high-accuracy reconstructed models for production, simulation, analysis, or validation.

Key Capabilities

Digitized Data Processing

- Import, generate, modify, and optimize raw meshes and scans

- Support for extremely large point clouds (up to billions of points)

- Clean, heal, repair, and refine noisy or incomplete scan data

Geometry Remodeling

- Semi-automatic workflows to rebuild exact geometry from scan data

- Recreate CAD-compliant surfaces, solids, and features

- Adjust or deform geometry to compensate displacement fields

- Remodel master shapes to counter dilatation, shrinkage, or spring-back

Digital Twin & Quality Validation

- Compare scanned physical parts with reference CAD models

- Highlight deviations, tolerances, and mismatch zones

- Validate production accuracy and conformity

3D Printing Preparation

- Validate geometry for AM workflows

- Generate STL or AMF files

- Ensure watertightness and integrity

Benefits

- High-quality reconstruction from any mesh or scan

- Reduce rework and accelerate prototype to production cycles

- Accurate geometry at first shot using semi-automatic tools

- Fast digital twin comparison to assess manufactured part validity

- Automated deformation compensation saves engineering time

- Seamless export to CAD, simulation, or 3D-printing pipelines

What’s New (Software Capability Enhancements)

- Import extremely large point clouds (billions of points)

- Build Fictive Edges on any curve type

- Improved auto-distributed sectioning

- New visibility-based filtering for Engineering IP Control

- Jacketting workflow support

What’s Included in the Service

- Scan / mesh import & cleaning

- Automatic and manual geometry remodeling

- Precision surface and solid reconstruction

- Deviation analysis vs. reference CAD

- Displacement-field-based shape compensation

- Export-ready files (STEP, IGES, STL, AMF, OBJ, etc.)

- Optional engineering report with visuals & measurements

Ideal For

- Industrial manufacturers

- Automotive, Aerospace, Marine engineering

- Prototype labs & 3D-printing shops

- Product designers & R&D teams

- Reverse-engineering firms

- Simulation engineering teams

Service Options (Shopify Variants)

Basic – $1,500

- Mesh import, cleanup, and refinement

- Basic surface reconstruction

- STL/AMF export

Professional – $4,500

- Full mesh remodeling

- CAD-accurate solid reconstruction

- Digital twin comparison

- Engineering PDF report

Enterprise – $9,500+

- Large dataset handling (hundreds of millions to billions of points)

- Displacement-field deformation compensation

- Manufacturing deviation study

- Multi-part assembly reconstruction

- Priority delivery

Share